A product realisation & design transfer specialist

Providing business advice, coaching and mentoring around complex R&D programs that have pressure on time, cost and quality.

Programs / projects that require international collaboration and where there is a need to grow and support high performing teams globally (particularly in China).

Ensuring product development is optimised for design transfer bringing long-term profitability and high customer satisfaction through reduce rework.

Engineering design transfer and supply chain localisation (i.e. manufacturing, supply chain and service) needs are met delivering an effective & efficient handover.

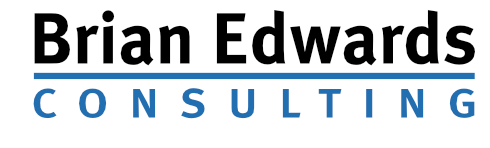

Our Process

We use the V module methodology as our process to ensure effective product realisation, ensuring profitability and efficient business when transferring product value to your customer. Click on the elements to find out more.

Business Requirement

We help ensure your business requirements align to the overall strategic direction ensuring research and development is aligned in supporting the realisation and transfer of your product to operations; for example: -

- Market access plans

- Regulatory strategy

- Operations strategy

- Life cycle

- Margin and costs targets

- Manufacturing and supply including localisation plans

- Post market and service strategy

With our support we help ensure high quality, on-time delivery. Proving the returns on investment, delighting your customers.

Design Requirements

We help ensure your project / program requirements are supporting the product definition to support an effective development to product realisation and design transfer, for example: -

Supply chain and manufacturing requirements are driving design as inputs

Design for manufacture

- Poka-Yoke, lean manufacturing

- Component selection (obsolescence management)

- Cost of Goods targets

Service

- Reliability targets

- Design life, reliability centre maintenance approach RCM

Install ability & Decommissioning

- Appropriate installations / decommissioning requirements

- Packaging and shipments requirements

With our support we help ensure high quality, on-time delivery. Proving the returns on investment, delighting your customers.

Concept Design

We help ensure the design review of the concept delivers the overall business benefits and the concept is ready to move into detail design.

We can help support reviews and look at trade-offs that have been made ensuring the concept can deliver the overall business needs including operations i.e. supply chain, manufacturing, service, as well as the functional commercial needs. The concept aligns with the top-level business strategy.

With our support we help ensure high quality, on-time delivery. Proving the returns on investment, delighting your customers.

Detail Design

We help coach, mentor the teams support ensuring the top-level requirements are broken down into sub-system module requirements, trade-offs are understood, and alignment is achieved across the functions before moving into implementation phase.

With our support we help ensure high quality, on-time delivery. Proving the returns on investment, delighting your customers.

Implementation

We can advise and support the design of the project / program delivery organisation to ensure it is effective and is setup to ensure efficient delivery.

During this phase we promote a continuous flow of Plan - Do - Check -Act ensuring the program can transition up the V curve efficiently with high quality, minimising future reworks.

We can help guide the distribution of business requirements into the modules / sub-systems and review that the teams have appropriate measures KPI’s, OKR’s, trackers in place and they are aligned to the overall product design level.

Integration

To help guide the integration process particularly ensuring no misunderstanding with 3 rd party and component module suppliers, complete full system integration is key.

- We help to ensure that all elements of the complete system come together including any 3 rd party products. We help ensure that boundaries are well defined with interfaces documented with definitions around criticality of performance. This is key to help with supply chain and V&V activities including any regulatory type testing that may be required

With our support we help ensure High Quality, On-Time delivery. Proving the Returns on Investment, Delighting your customers.

Verification

Along with verifying the product functional design, we can support the review verification activities to ensure that they are testing and verifying the product meets its business requirements.

- Cost of goods

- Lead-times

- Engineering and manufacturing structure BOM (bills of materials)

- FRU field replaceable units (spares)

At this stage we encourage and support manufacturing, supply chain, service and training to be connected to the process, defects are tracked, and corrective actions are in place.

With our support we help ensure high quality, on-time delivery. Proving the returns on investment, delighting your customers.

Validation

At this key phase we help ensuring the design is ready to transfer out of engineering to operations and the technical file is ready.

- We help ensure that you have the formal evidence required in meeting the design requirements including manufacturing and supply chain inputs.

- In a large-scale project this may require a pilot activity, ensuring product supply, install ability requirements and user ability are formally meet along with key customer feedback.

- We can support the review of the technical file to meet the regulatory needs for market access CE, FDA and NMPA China where the test method can be more descriptive, including manufacturing supply chain evidence.

With our support we help ensure high quality, on-time delivery. Proving the returns on investment, delighting your customers.

Design transfer

This is the final stage as the product moves into normative supply and delivery. We help guide and support the handover ensuring that the product still aligns with the overall business strategy.

- We help ensure that the day-to-day activities of procurement, manufacturing, order fulfilment, installation, training and service can be performed efficiently.

- Post market surveillance, FRACAS (field reporting and corrective action system) is running smoothly.

- We help facilitate lessons learnt as part of the design transfer.

With our support we help ensure high quality, on-time delivery. Proving the returns on investment, delighting your customers.

Business Requirements

We help ensure your business requirements align to the overall strategic direction ensuring research and development is aligned in supporting the realisation and transfer of your product to operations; for example:

- Market access plans

- Regulatory strategy

- Operations strategy

- Life cycle

- Margin & cost targets

- Manafcturing and supply including localisation plans

- Post market and service strategy

With our support we help ensure high quality, on-time delivery. Proving the returns on investment, delighting your customers.

Design Requirements

We help ensure your project / program requirements are supporting the product definition to support an effective development to product realisation and design transfer, for example:

Supply chain and manufacturing requirements are driving design as inputs

Design for manufacture

- Poka-Yoke, lean manufacturing

- Component selection (obsolescence management)

- Cost of goods targets

Service

- Reliability targets

- Design life, reliability centre maintenance approach RCM

Install ability & decommissioning

- Appropriate installations / decommissioning requirements

- Packaging and shipments requirements

With our support we help ensure high quality, on-time delivery. Proving the returns on investment, delighting your customers.

Concept Design

We help ensure the design review of the concept delivers the overall business benefits and the concept is ready to move into detail design.

We can help support reviews and look at trade-offs that have been made ensuring the concept can deliver the overall business needs including operations (i.e. supply chain, manufacturing, service) as well as the functional commercial needs. The concept aligns with the top-level business strategy.

With our support we help ensure high quality, on-time delivery. Proving the returns on investment, delighting your customers.

Detail Design

We help coach and mentor the teams support, ensuring the top-level requirements are broken down into sub-system module requirements, trade-offs are understood, and alignment is achieved across the functions before moving into implementation phase.

With our support we help ensure high quality, on-time delivery. Proving the returns on investment, delighting your customers.

Implementation

We can advise and support the design of the project / program delivery organisation to ensure it is effective and is setup to ensure efficient delivery.

During this phase we promote a continuous flow of Plan - Do - Check - Act, ensuing the program can transition up the V curve efficiently with high quality, minimising future reworks.

We can help guide the distribution of business requirements into the modules / sub-systems and review that the teams have appropriate measures KPI’s, OKR’s, trackers in place and they are aligned to the overall product design level.

With our support we help ensure high quality, on-time delivery. Proving the returns on investment, delighting your customers.

Integration

To help guide the integration process particularly ensuring no misunderstanding with 3rd party and component module suppliers, complete full system integration is key.

We help to ensure that all elements of the complete system come together including any 3rd party products. We help ensure that boundaries are well defined with interfaces documented with definitions around criticality of performance. This is key to help with supply chain and V&V activities including any regulatory type testing that may be required.

With our support we help ensure high quality, on-time delivery. Proving the returns on investment, delighting your customers.

Verification

Along with verifying the product functional design, we can support the review verification activities to ensure that they are testing and verifying the product meets its business requirements.

- Cost of goods

- Lead-times

- Engineering and manufacturing structure BOM (bills of materials)

- FRU field replaceable units (spares)

At this stage we encourage and support manufacturing, supply chain, service and training to be connected to the process, defects are tracked, and corrective actions are in place.

With our support we help ensure high quality, on-time delivery. Proving the returns on investment, delighting your customers.

Validation

At this key phase we help ensuring the design is ready to transfer out of engineering to operations and the technical file is ready.

- We help ensure that you have the formal evidence required in meeting the design requirements including manufacturing and supply chain inputs.

- In a large-scale project this may require a pilot activity, ensuring product supply, install ability requirements and user ability are formally meet along with key customer feedback.

- We can support the review of the technical file to meet the regulatory needs for market access CE, FDA and NMPA China, where the test method can be more descriptive, including manufacturing supply chain evidence.

With our support we help ensure high quality, on-time delivery. Proving the returns on investment, delighting your customers.

Design Transfer

This is the final stage as the product moves into normative supply and delivery. We help guide and support the handover ensuring that the product still aligns with the overall business strategy.

- We help ensure that the day-to-day activities of procurement, manufacturing, order fulfilment, installation, training and service can be performed efficiently.

- Post market surveillance, FRACAS (field reporting and corrective action system) is running smoothly

- We help facilitate lessons learnt as part of the design transfer

With our support we help ensure high quality, on-time delivery. Proving the returns on investment, delighting your customers.

Brian Edwards Story

I have worked in the medical solution industry for the past 37 years during which time I have run various programs and managed a multi-million-dollar business in China. I supported and developed highly competent teams to innovate, manufacture, maintain and to supply globally medical linear accelerators.

I have led from initial concept to full release a fully integrated medical linear accelerator systems “Elekta Harmony” as head of program. It was delivered on time, to budget and meet customer needs. I have also managed various manufacturing and design transfer projects including localisation of supply chains.

What to Expect

Evaluate

Goal Set